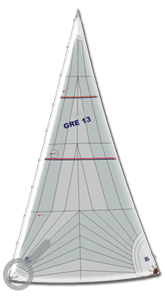

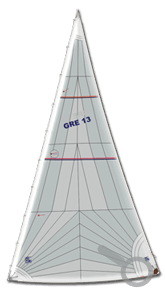

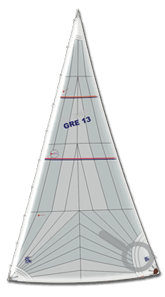

Genoa Snap Shackle Cruising Performance Swan 36

Specifications

▲ DESIGN WITH PROSAIL

▲ PRODUCTION SYSTEM: A.R.C.(ADVANCED REGULATION CODE)

▲ USAGE: OFFSHORE SAILING

▲ CUTTING: RADIAL CUT

▲ CLOTH : CHALLENGE, BAINBRIDGE, CONTENDER , DIMENSION POLYANT

▲ UV PROTECTION ON LEECH AND FOOT: SUNBRELLA MARINE PLUS

▲ REEF POINT

▲ STAINLESS STEEL RINGS ON CLEW BAINBRIDGE

▲ LEATHER FINISH

▲ LEECH LINE: 3-6mm Polyester rope

▲ FOOT LINE: 3-6mm Polyester rope

▲ WEBBING HEAD / TACK & CLEW: Polyester

▲ EXTRA WEBBING REINFORCED ON RINGS BAINBRIDGE

▲ PANEL’S STITCHING: ONE 3 – STITCH

▲ SECTION’S STITCHING: 3 or 4 3-STITCH

▲ DRAFT STRIPES

▲ T-TAILS

▲ HIGH ADHESION DOUBLE SIDED SEAMING TAPE ACRYLIC BASED SILICON

▲ WEBBING HEAD & TACK: Polyester

▲ THREAD: HEMINGWAY & BARTLETT BONDED DACRON “ANTI-WICK” V – 92 & V – 138

▲ SAIL-BAG: PRINTED NAME AND TYPE OF BOAT

▲ 3 YEARS GUARANTEE

Extra Options :

▲ WINDOW T-TAILS

▲ NUMBERS – LETTERS

Our CDX Polyester Cruising laminates made with ZigZag yarn technology enable you to have a sail made out of radial panels that matches the modern rigging of your yacht.The yarns in ZigZag-reinforced laminates are laid at angles such that the forces in the sail are distributed evenly over the radial panels. This results in a sail with excellent ability to retain its shape, giving you more efficient sailing in varying wind strengths, without impacting on the ease of handling of your sail. You can reef later because the sail will remain flatter in increasing winds. Your yacht will sail faster and you can point higher with less heeling.

CDX Polyester Cruising Laminate

Our ZigZag fibre layout ensures efficient support and distribution of the loads over the radial panels in your sail. The effect of this fibre layout is to reduce the load on the Mylar film which helps the sail to retain its shape longer.

UV treated Polyester taffetas on both sides of the laminate for extra protection

Leather Finish

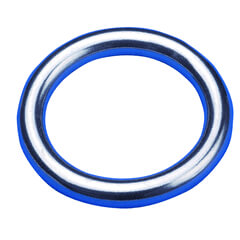

Rings 30mm x 6mm Welded 316 Stainless Steel

▲Manufactured from Type 316 stainless steel, which is chemically passivated after welding to reduce the risk of staining.

▲TIG welded maximising strength.

▲Small diameter rings with the same size bar diameter will deform at a higher load, although both will have similar tensile strength.

Maxi Rings – Stainless Steel

▲Bainbridge Maxi Rings are manufactured from Type 316 stainless steel, which is cleaned and passivated after welding to reduce the risk of staining.

▲TIG welded maximises strength.

▲Reinforcing bar reduces potential distortion under high load.

Swedish Forged Brass Piston Hanks

Swedish brass jib hanks are renowned world-wide for quality, reliability and ease of fitting.

▲ Forged from marine quality brass and fitted with a stainless steel spring.

▲ B516 has a jaw opening of 25mm and internal dimensions of 25mm x 29mm. It is designed for use over forestay systems for stor jibs, not for large genoas.

Heavy Weight Polyester

▲Strong, low stretch webbing ideal for strapping rings on sails

▲Flat, non_tubular webbing

▲Excellent UV resistance

▲Very low stretch

▲Minimal shrinkage

▲Available only on full reels

Super Heavy Weight – Tubular

▲ Available only on full reels.

▲ All products are nylon except E124 Dacron

Stainless Steel Welded Hardware

All welded stainless steel fittings are manufactured from type 316 stainless steel, which is chemically cleaned and passivated after welding to reduce the risk of staining. TIG welding maximises strength.